Hydraulic Puller and Separators

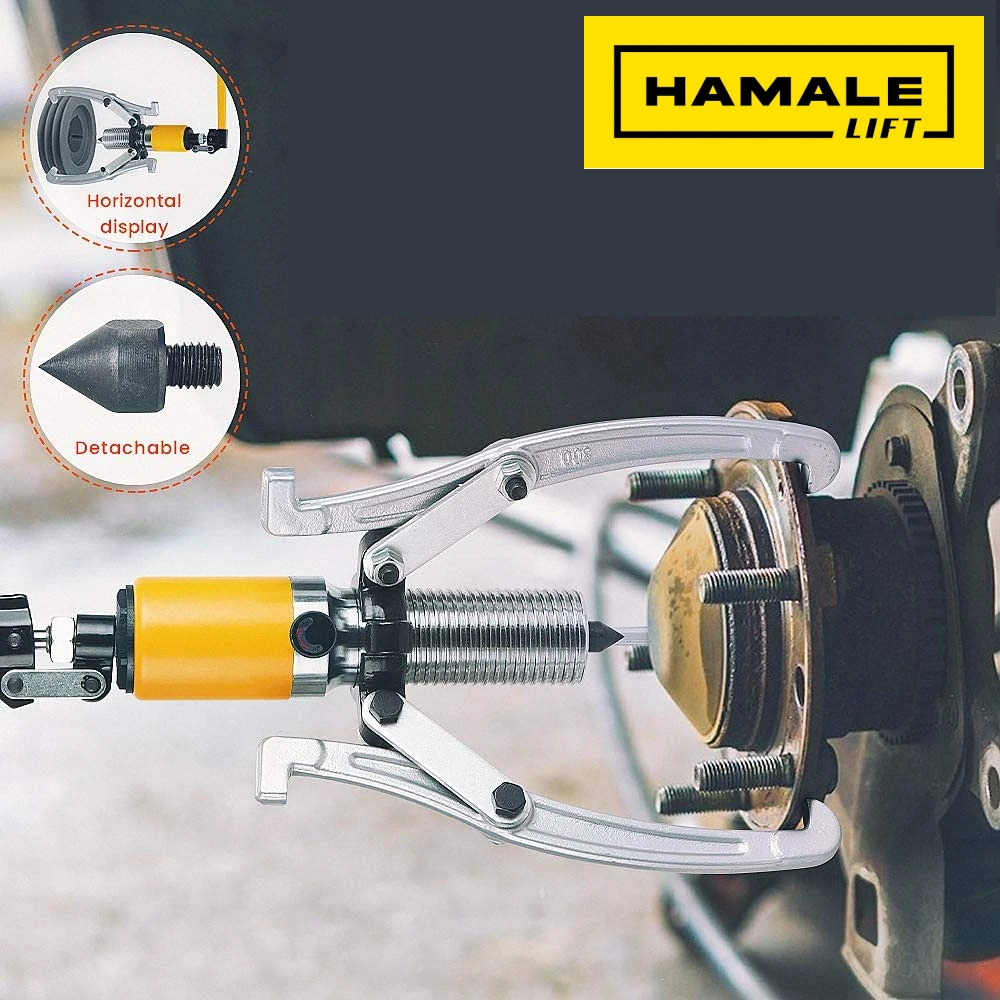

5 Ton Self Contained Hydraulic Pullers

10 Ton Self Contained Hydraulic Pullers

20 Ton Self Contained Hydraulic Pullers

30 Ton Self Contained Hydraulic Pullers

50 Ton Self Contained Hydraulic Pullers

5 Ton Hydraulic Puller and Hand Pump sets

10 Ton Hydraulic Puller and Hand Pump sets

20 Ton Hydraulic Puller and Hand Pump sets

30 Ton Hydraulic Puller and Hand Pump sets

50 Ton Hydraulic Puller and Hand Pump sets

14-tons-hydraulic-wedge-spreader

8-tons-mechanical-wedge-spreader

It eliminates flange damage and the risk of pipe failure on the installation. Only 6 mm of access clearance is required for the tabs to engage. It provides safe use with safety block and stepped blocks. Ratchet handle is provided in the product content.

5 Tons Hydraulic Flange Spreader

●Lightweight, ergono mic design for ease of use. ●Adjustable jaw widths from 70 to 216 mm for a wide range of applications. ●Single-acting, spring return. ●Supplied with R2 3/8 male coupler and dust cap. ●Operated by hydraulic pump with rated pressure of 700 bar.Hand pump not included

10 Tons Hydraulic Flange Spreader

●Lightweight, ergono mic design for ease of use. ●Adjustable jaw widths from 70 to 216 mm for a wide range of applications. ●Single-acting, spring return. ●Supplied with R2 3/8 male coupler and dust cap. ●Operated by hydraulic pump with rated pressure of 700 bar.Hand pump not included

What is Hydraulic Puller?

What Should We Consider When Choosing a Hydraulic Puller?

Some details will contribute to making your work easier in the selection of hydraulic puller. First of all, when determining the capacity of the product, determine the corrosion status of the part, the force required for the area of the friction surface, and whether the feet to be gripped are suitable according to the dimensions that will grip the part. You can choose the type of puller according to the condition of the place to be used.

Pullet Type:

Model with pump

Its general feature is on the hydraulic oil pump and it does not need an external power unit. On this type of pullers, they need more free connection areas for the pump and pump arm to work. Horizontal and reverse use is possible.

Model with Remote Hose Pump;

General feature. It produces external power to the puller with a pump with a hose of approximately 1.5 mt outside the power unit. This type of puller has a more compact structure and allows use in narrow areas. Another feature is to allow the personnel to stand at a safe control distance when using it in dangerous areas. Horizontal and the possibility of use in the opposite direction is available.

What is a Separator?

Our products are divided into two classes as hydraulic separator and mechanical separator. The general purpose of the products is to separate the surfaces that remain adhered for a long time, to open very narrow distances (min.5mm) or to align them precisely or to bring them to the tailor. They are indispensable products for a wide variety of needs such as separating etc.